Leca clay balls expanded clay pebbles characteristic.

LECA clay ball density

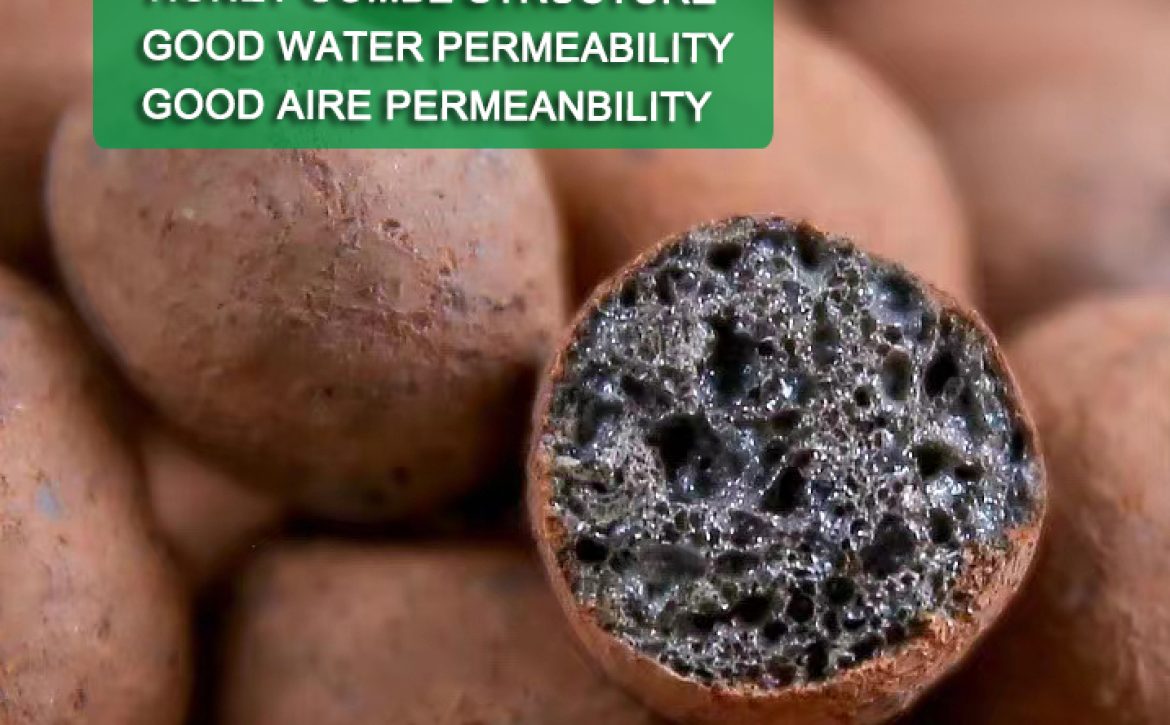

Leca clay balls expanded clay pebbles is a kind of lightweight aggregate produced by foaming in a rotary kiln. It has a spherical shape, a smooth and hard surface, and a honeycomb inside, which has the characteristics of low density, low thermal conductivity and high strength. In the refractory industry, leca clay balls expanded clay pebbless are mainly used as aggregates for heat-insulating refractory materials. The bulk density of the leca clay balls expanded clay pebbles itself is less than 1100kg/m3, generally 300-900kg/m3. The density of concrete made of leca clay balls expanded clay pebbless as aggregate is 1100-1800kg/m3.

Leca clay ball concrete compressive strength

The corresponding compressive strength of leca clay ball concrete is 30.5-40.0Mpa. It is hard on the outside, but there are many micropores inside. These micropores give leca clay balls light weight properties. The concrete density of No. 200 fly ash leca clay balls expanded clay pebbles is about 1600kg/m3. At present, the sand of my country’s leca clay balls expanded clay pebbless is mainly used for petroleum proppant, and it is also one of the sand varieties of leca currently in demand, also known as sand for oil fracturing proppant leca.

Advantage of clay aggregate concrete

The concrete of ordinary fly clay ball or the clay aggregate blocks integrate heat preservation, earthquake resistance, frost resistance, fire resistance and other properties. Especially the fire resistance is more than 4 times that of ordinary concrete. For the same refractory period, the thickness of the concrete plate of the expanded clay pebbles is 20% thinner than that of ordinary concrete.

clay aggregate blocks integrate heat preservation.

In addition, expanded clay pebbless can also be used to prepare refractory concrete with a refractoriness below 1200°C. At a high temperature of 650 ° C, the concrete of expanded clay pebbles can maintain 85% of the strength at room temperature. Ordinary concrete can only maintain 35% to 75% of its strength at room temperature.