Since the 1980s, the biological aerated filter (BAF) has received widespread attention and has become a research hotspot at home and abroad. As a new type of high-efficiency biofilm sewage treatment technology, it has good applications in the removal of organic matter in sewage, nitrogen and phosphorus removal, and industrial wastewater treatment.

1. Biological aerated filter (BAF)

1) Biological aerated filter (BAF) – basic principle

The basic principle of BAF is to use granular fillers as the medium to achieve the purpose of removing pollutants in water through the adsorption and interception of biofilms and extracellular polymers attached to the fillers, the oxidative decomposition of microorganisms, and the hierarchical predation of food chains formed along the direction of water flow. The function of denitrification and phosphorus removal is realized by utilizing the existence of aerobic and anoxic regions in the reactor.

2) Biological aerated filter (BAF) – characteristics

BAF features: This technology has the advantages of good effluent quality, short hydraulic retention time, small footprint, low investment and operating costs, strong impact load resistance and convenient management. It is an environmentally friendly, economical, efficient and energy-saving sewage treatment. New technology, which can realize the renewable and sustainable utilization of water resources, is very suitable for the shortage of water resources, insufficient funds, and relatively backward technology in my country’s sewage treatment. We should increase research and development efforts. At the same time, you can view more technical documents on China Sewage Treatment Engineering Network.

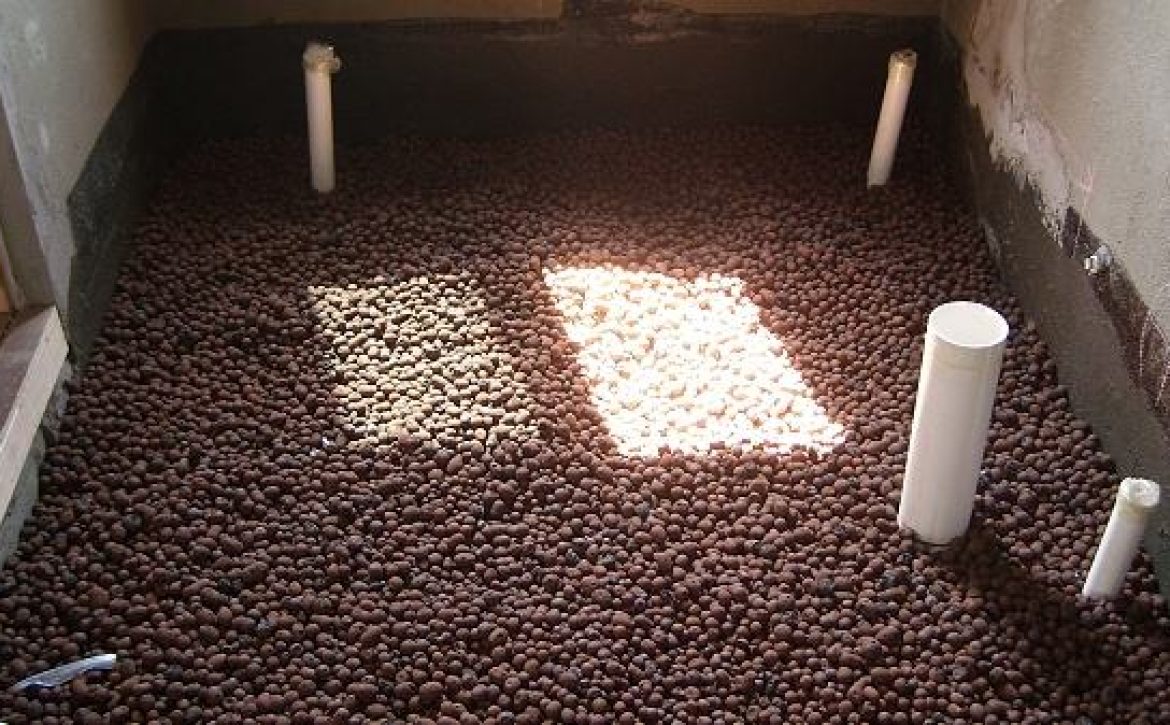

3) Biological aerated filter (BAF) – filler

In the biological aerated filter, the filler is the core component, which is extremely important to the treatment effect and operation control of the biological aerated filter. First of all, as the carrier of microorganisms, the filler affects the growth, reproduction, shedding, shape and spatial structure of the biofilm, provides a stable environment for the microorganisms to inhabit and reproduce, and can maintain a large amount of microorganisms; secondly, the filler is the biofilm in the reactor. The place where the biofilm is in contact with the wastewater, and can have a mandatory turbulent effect on the water flow, so that the wastewater can be redistributed; in addition, the filler is used as a medium for removing suspended solids, and its filtration performance affects the biological aerated filter. removal effect.

2. Types and characteristics of biological filter materials

1) Types of biological filter materials

The fillers used in the biological aerated filter can be divided into inorganic fillers and organic polymer fillers according to the different raw materials used.

Commonly used inorganic fillers are: clay aggregate, coke, quartz sand, activated carbon, expanded aluminosilicate, etc.);

Organic polymer fillers include: polystyrene, polyvinyl chloride, polypropylene PE, various resins, plastics (including various foam materials), fibers

2) Characteristics of biological fillers

①Granular filler: This is the earliest filler that has been used up to now, and its material is inorganic clay aggregate or quartz sand. The main characteristics of this type of packing are rough surface, easy to attach organisms, and strong ability to intercept suspended pollutants. The disadvantage is that it has large resistance and is easy to block.

② Irregular granular packing: Raschig ring (RaschingRing) Pall ring (PallRing) in the early days, currently commonly used are Hacketten ball (Hacketten) and multi-faceted hollow ball, etc., which can be made of ceramic graphite, plastic or metal. Simple structure, low price, but uneven fluid distribution;

③Fiberglass or plastic filler: smooth surface, poor biofilm adhesion, easy to age, often prone to clogging in actual use. The water flow in the soft filler is not ideal, and it is easy to produce balls, which greatly reduces the surface area, and then produces anaerobic effect inside the balls, affecting the treatment effect;

④ Activated carbon particles: large specific surface area, many pores, but expensive, and because the surface pore size is too small, most microporous microorganisms cannot be used;

⑤Plastic fiber filler: light weight, hard, but smooth surface, small porosity, not easy to hang film; fiber filler generally has shortcomings such as easy agglomeration and difficult filling;

⑥Honeycomb or corrugated plate packing: the material is usually glass fiber reinforced plastic or plastic (polyethylene polystyrene and polypropylene, etc.), and its main advantages are high void ratio, simple structure, light weight but high strength, good anti-corrosion performance, and aging resistance. The main disadvantages such as the easy shedding of organisms are that the growth and shedding balance of organisms on the surface of the filler is not easy to control, and it is difficult to obtain a uniform flow rate spherical lightweight clay aggregate in the filler;

⑦Spherical lightweight clay aggregate: It is made of clay as raw material, adding appropriate chemical raw materials as expansion agent, and firing at high temperature. It has many advantages that other traditional fillers do not have: high strength, large porosity, large specific surface area, good chemical stability, suitable density, and strong bio-adhesion.

3.Effect of filler on the efficiency of biological aerated filter

1) Influence of filler particle size

The particle size of the filler has an important influence on the treatment efficiency and operation cycle of the biological aerated filter. The smaller the particle size of the filler, the better the treatment effect. Backwashing, and it is not easy to play the role of the deep layer of the filler. Therefore, the selection of filler for the biological aerated filter needs to consider the treatment efficiency and operation cycle of the filter at the same time, and optimize the selection according to the water quality and treatment requirements of the filter.

2) The density of the filler

The density of the biofilter filler is related to the backwash intensity of the biofilter. The greater the density, the greater the backwash intensity, and the greater the energy consumption; therefore, when selecting the biofilter filler, it is necessary to measure the various fillers. Density. Units with waste water that need to be treated can also consult companies with similar sewage treatment experience on the Sewage Bao project service platform.

3) Filling layer height

The height of the filter layer is related to the quality of the effluent. Within a certain range, increasing the height of the filter layer can improve the treatment effect of the filter and ensure the quality of the effluent, but at the same time, the increased sewage lifting head and backwashing intensity will lead to increased energy consumption.

4. A new type of filler – biological clay aggregate

1) Types of biological clay aggregate

① Spherical lightweight clay aggregate: clay (mainly composed of metaaluminosilicate) is used as the main raw material, and appropriate chemical raw materials are added as expansion agents, which are fired at high temperature. The clay aggregate is easy for microorganisms to grow, fast to form a film, and after contacting with nutrients in wastewater, it has a high transfer rate, fast adsorption and oxidation speed, and high treatment efficiency.

② Fly ash clay aggregate: Fly ash clay aggregate is generally spherical, the surface is rough and hard, and there are many micropores in the honeycomb shape. The advantages of fly ash clay aggregate and its products mainly lie in four aspects: excellent performance, good economic benefits, strong construction adaptability and wide application range.

③ Nano-modified clay aggregate: The dispersed phase of nano-powder particles has a large specific surface area and strong interface effect, and is attached to the surface of the clay aggregate filler and the surface of the internal pores to provide high roughness for the film formation and start-up of the reactor, thereby improving Bacterial proliferation rate and biofilm formation rate.

④ Korean EPP filler: The filler is made by mixing polypropylene resin powder and powdered activated carbon in a certain proportion to form a masterbatch containing activated carbon, and then extruding the masterbatch to produce expanded polypropylene filler. Because the filler contains powdered activated carbon, it has strong organic adsorption capacity and porosity suitable for microbial growth.

⑤ Sewage plant sludge and river bottom sludge filler: a new type of sludge filler prepared with sewage plant sludge or river bottom sludge as the main raw material and clay and water glass as additives. Its removal effect on ammonia nitrogen, COD, turbidity, etc. is better than ordinary clay aggregate, meets the requirements of biofilm carrier, and creates another way for sludge resource utilization.

2) Performance indicators suitable for biofilter fillers

The clay aggregate generally used in BAFs is selected based on:

① The particle size is above 5mm (the smaller the particle size, the more clogged it will be);

② The bulk density is generally between 500~800kg/m³ (it cannot float on the water surface and depends on the upstream velocity of BAFs);

③ The higher the water absorption, the better;

④ Have a certain compressive strength (above 2.5Mpa);

⑤ The sphericity coefficient is above 0.95;

⑥ Color is not the standard to determine the quality of clay aggregate;

⑦ The specific surface area is preferably 8.0㎡/g (the bigger the better);

⑧ The slag dropping rate is less than 0.5%;

⑨ The soluble rate of hydrochloric acid is less than 1%.

5. Biological sludge clay aggregate

my country has developed the “sludge bio-clay aggregate” production technology, and successfully prepared a new type of biological aerated filter filler – sludge bio-clay aggregate. In the research, it was found that compared with commercial clay aggregate, sludge bio-clay aggregate has the characteristics of high porosity, high specific surface area, and high efficiency of wastewater treatment. In addition, since the sludge contains a variety of trace elements, it can promote the growth of microorganisms very well, so it is easy to form a film, and has higher removal efficiency of nitrogen and phosphorus and COD for industrial wastewater and domestic sewage.

The internal pores of sludge biological clay aggregate are extremely developed, and there are 300-600 μm large pores between the skeletons and 30-50 μm small pores inside the skeletons. The large pores between the skeletons can provide an environment for the growth of anaerobic or facultative microorganisms, and increase the specific surface area of the clay aggregate. The small pores inside the skeleton are basically not connected to the large external space, which mainly plays a role in reducing the weight of the clay aggregate. This kind of sludge biological clay aggregate further proves that it meets the requirements of BAF filler in terms of micro-structure.