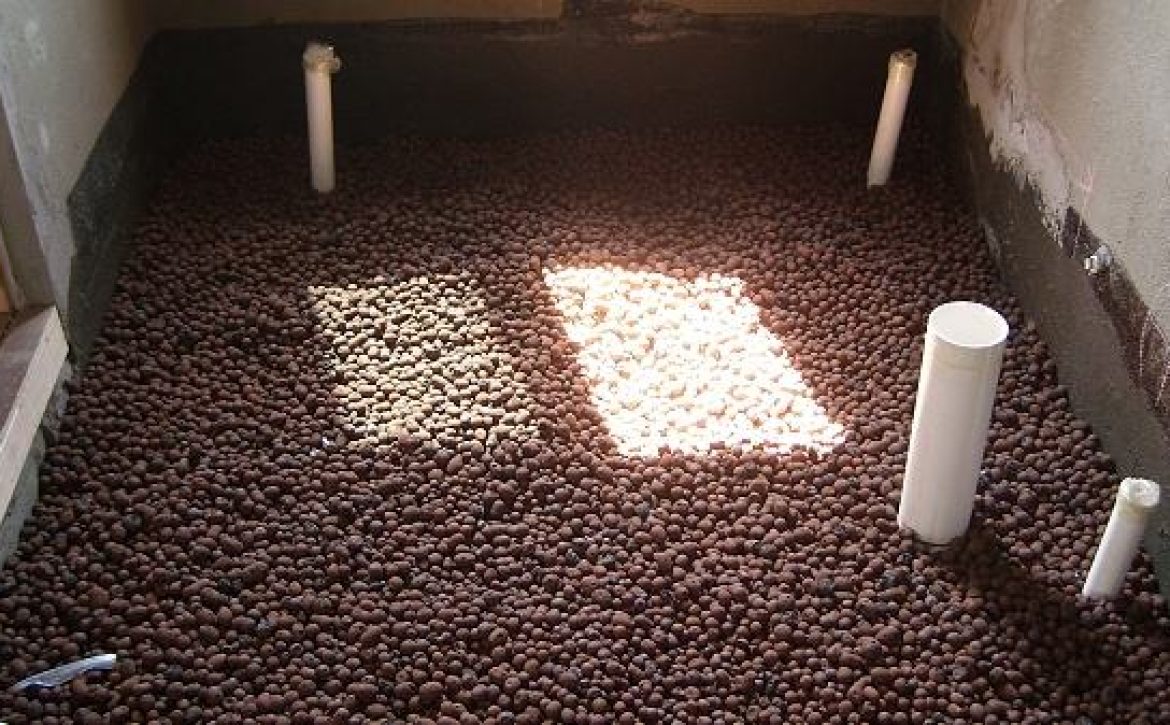

Backfill clay aggregates or ECA is used for high-rise building structure concrete, the top roof has good thermal insulation effect, and is packed in woven bags. It can be used in civil engineering construction, preparation of various concrete, roof insulation, moisture-proof insulation of the ground floor of buildings, anti-seepage moisture-proof insulation outside the walls of underground buildings and under the ground, soilless cultivation (hydroponics), sewage filter materials, etc. clay aggregates or ECA is widely used in planted roofs (underground car parks) as a drainage material. Used in high-rise buildings, long-span buildings; soilless cultivation (hydroponics), bridges, sewage treatment, etc. have unique functions

clay aggregates or ECA has:

1. Small density and light weight

2. Heat preservation and heat insulation

3. Good fire resistance

4. Good shock resistance

5. Low water absorption, good frost resistance and durability

6. Excellent impermeability

7. Excellent alkali-aggregate reaction ability

8. Strong adaptability